Aerospace Quality, Hometown Convenience

Owned and operated by a premier aircraft manufacturing and modification facility, our machine shop facilities meet stringent FAA requirements for aerospace manufacturing. That means you can count on the same attention to detail and quality craftsmanship we use for mission-critical components in multi-million dollar aircraft.

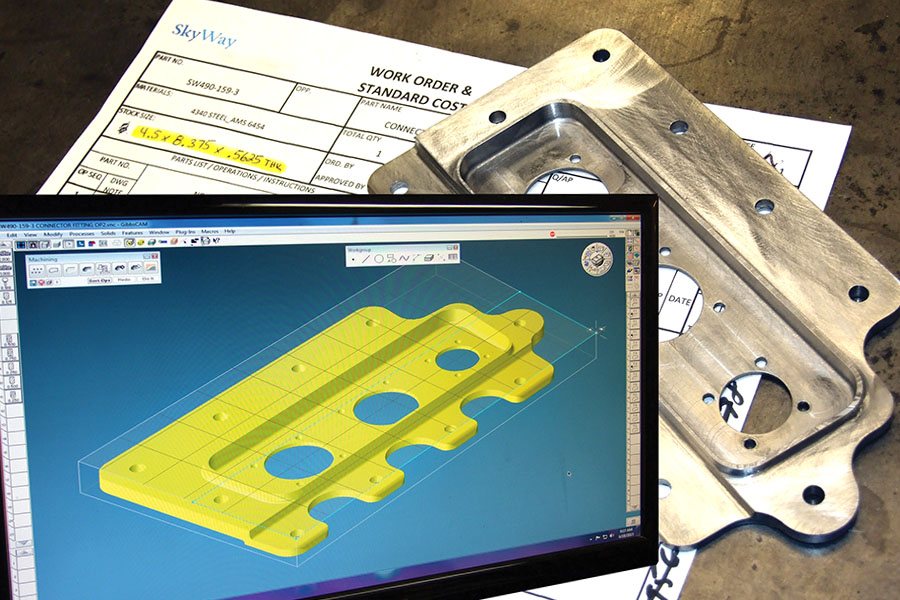

Experienced technicians will help you bring your design to life, whether in aluminum, steel, or something more exotic. Our in-house waterjet cutter and multi-axis CNC router can handle brittle and/or heat-sensitive materials with ease. It’s perfect for everything from custom shaped stone countertops to elegantly routed doors and cabinetry to unusual signage and display projects.

We offer the latest in sophisticated CNC machining technology, including one of the largest abrasive waterjet cutting machines in the region. A wide variety of forming and fabrication technologies are on-site, including CNC milling, alodyning, sheet metal bending, two open-face filtered paint booths and more. Our flexible and programmable equipment is ideal for short-to-medium production runs or one-off prototyping for R&D projects.

PARTIAL LIST OF EQUIPMENT

IN HOUSE CAPABILITIES

Whether your needs are for a one-off prototype, a short production run or logistical support for custom installation or parts fabrication, SkyWay Manufacturing is ready to help shape your goals into reality.